microFLUID

microFLUID (micro-Fabrication of polymeric Lab-on-a-chip by Ultrafast lasers with Integrated optical Detection) is an European project under the Seventh Framework Programme (FP7), coordinated by the Institute for photonics and nanotechnologies – CNR (Milan, Italy), which was attended by nine companies and universities coming from Italy, Germany, France, UK and Switzerland:

- Laser Zentrum Hannover (Germany)

- Institut d’Alembert – ENS Cachan- CNRS (France)

- Politecnico di Milano (Italy)

- University of Manchester (U.K.)

- Agrolabo SpA (Italy)

- Centre Suisse d’Electronique et de Microtechnique (Switzerland)

- Microfluidic Chip Shop GmbH (Germany)

- Institut für Mikrotechnik Mainz GmbH (Germany)

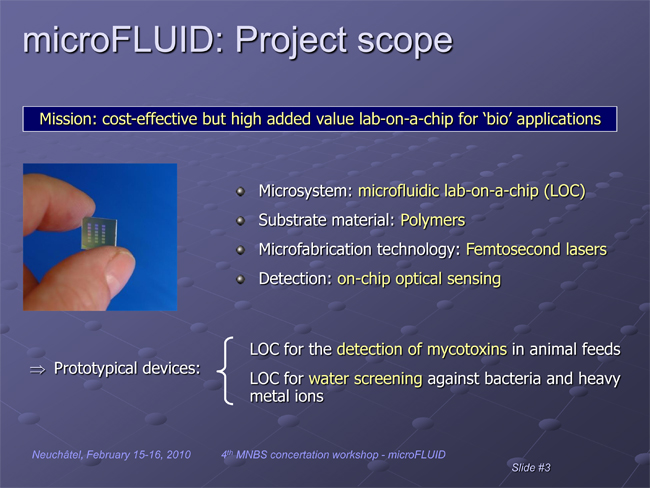

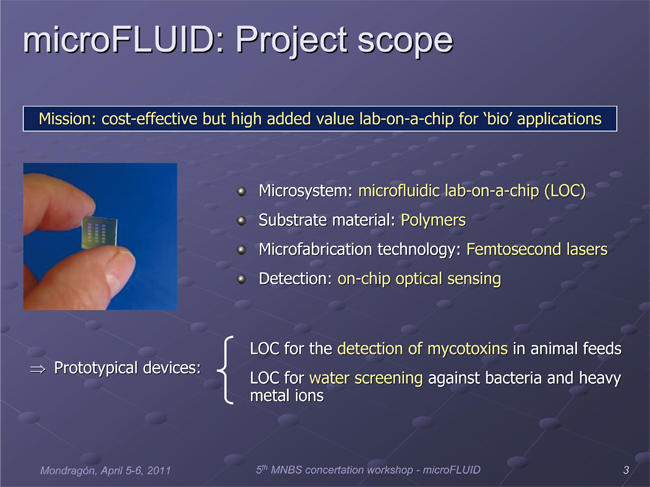

The main target of the project was the use of femtosecond lasers for the development of highly flexible micro-manufacturing platforms for polymeric LOCs (Lab-on-chip) with integrated optical detection, and the creation of cheap and portable biophotonic microsystems.

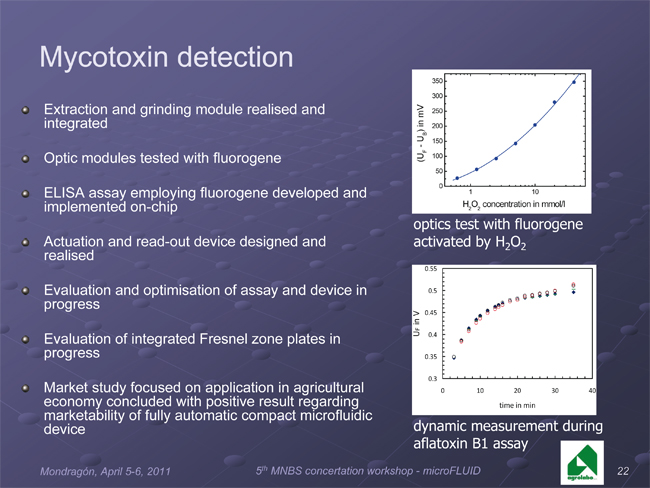

In particular, Agrolabo SpA was involved in the development of a rapid and simple prototype device for the detection of mycotoxins in different types of samples (cereals, milk, dried fruit, spices …), in order to provide quicker results than the other commercial tests.

The project was presented in 2010 and 2011, respectively in Switzerland and Spain:

4th MNBS Concertation Workshop, Neuchâtel, 15-16 Febbraio, 2010

5th MNBS Concertation Workshop, Mondragón, Spagna, 5-6 Aprile, 2011

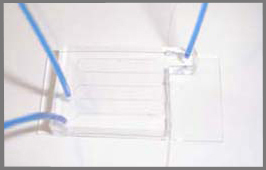

Lab-on-chips (LOCs) are microsystems capable of handling small quantities (from micro to nanoliters) of fluids in microfluidic channels with dimensions from ten to one hundred micrometers: they have enormous potential application in different fields of chemistry and life sciences. Despite their potential, commercial exploitation of LOCs has so far been slow.

Two innovations that could promote the spread of LOCs are:

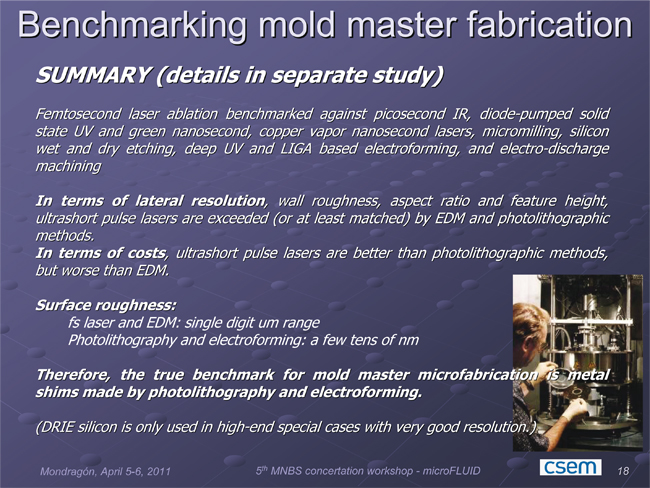

- a manufacturing technology with rapid and low-cost prototyping capabilities,

- an on-chip integrated optical detection.

Polymers are rapidly emerging as the material of choice for LOC substrates due to their low cost, favorable optical properties and ease of processing. Many of these are already commercially available, but an almost unlimited number of changes are possible in the composition for further optimization of the chosen structure.

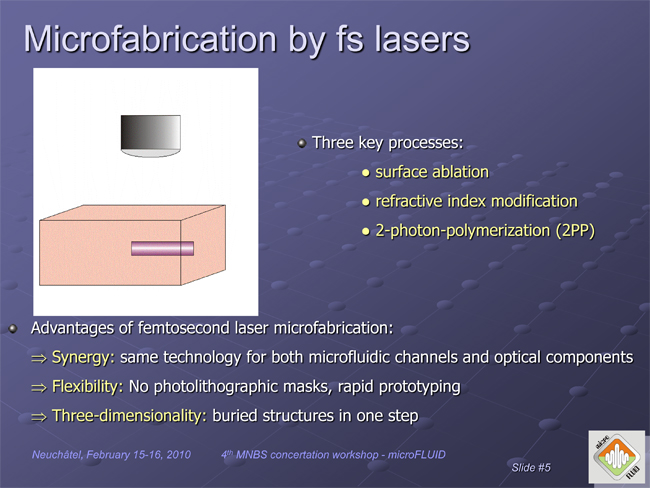

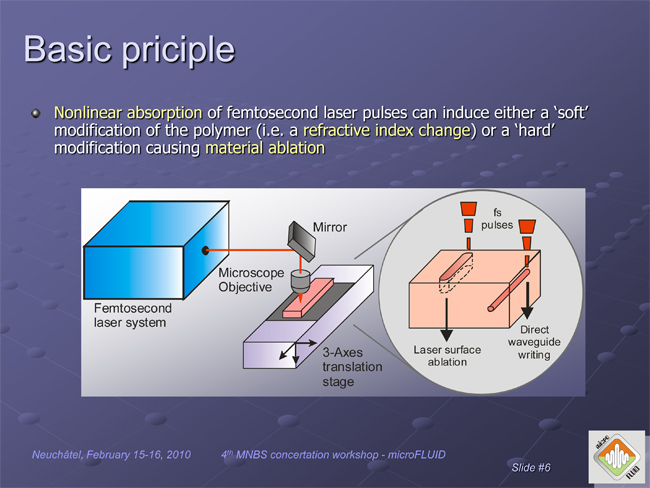

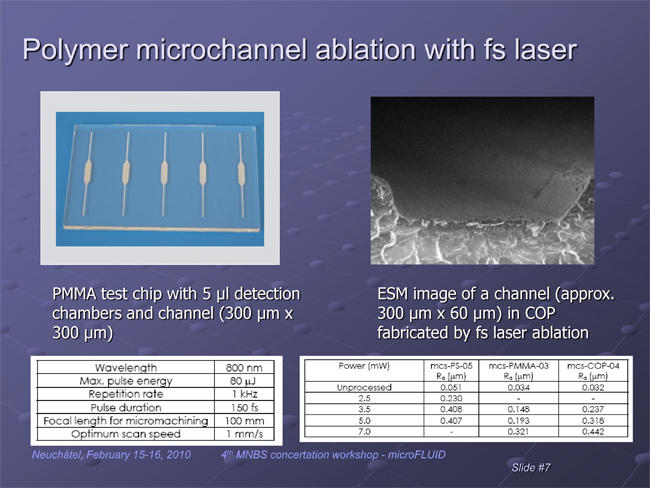

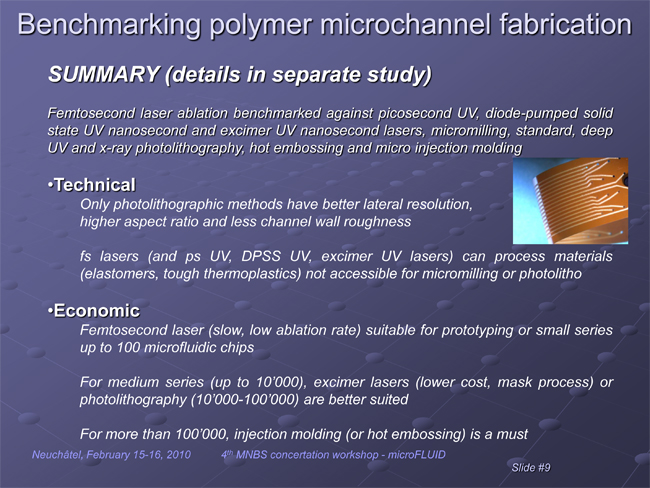

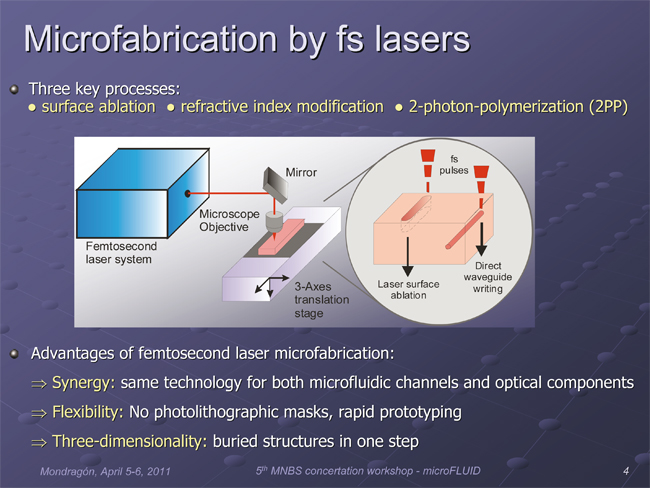

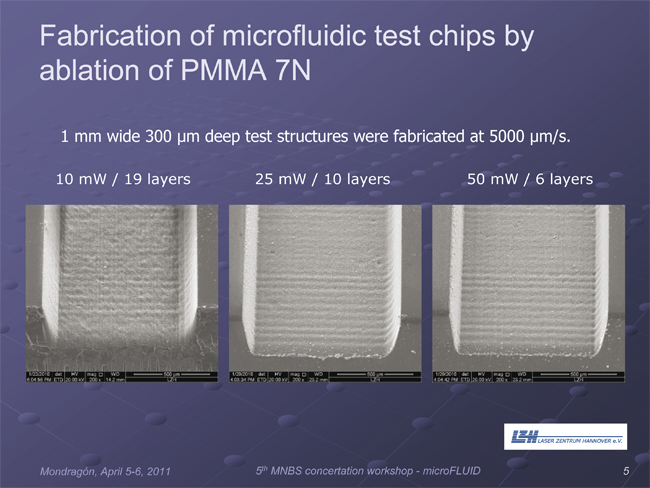

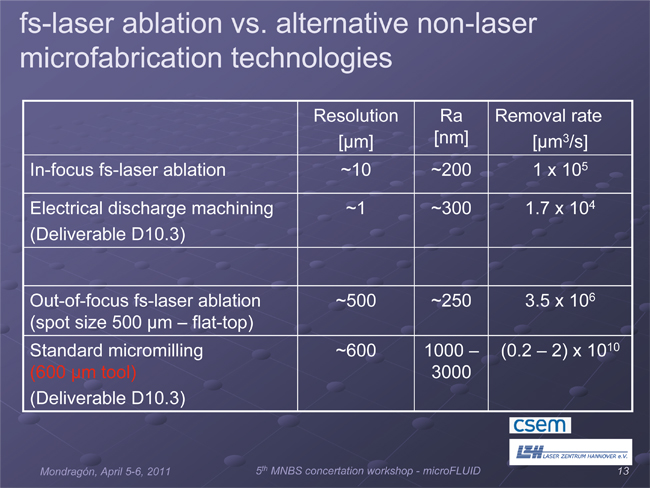

Laser fabrication is a flexible, low-cost process and allows for the creation of a variety of microstructures in a wide range of materials. In particular, femtosecond lasers, due to their peculiar regime of interaction with light, offer unique microfabrication capabilities. For a long time, their use was practically limited by their high cost and complexity. Recent technological progress has greatly improved their performance and reliability, making them available as a practical micromachining tool. Femtosecond laser fabrication can be used in different phases of the production cycle: (i) rapid prototyping of the microfluidic chip; (ii) direct fabrication of photonic components on the LOC for integrated optical sensing. The main goal of the microFLUID project is the use of femtosecond lasers as a new highly flexible microfabrication platform for polymeric LOCs with integrated optical sensing, for the construction of low-cost and truly portable biophotonic microsystems. The scientific developments of the project will be applied to two prototype devices:

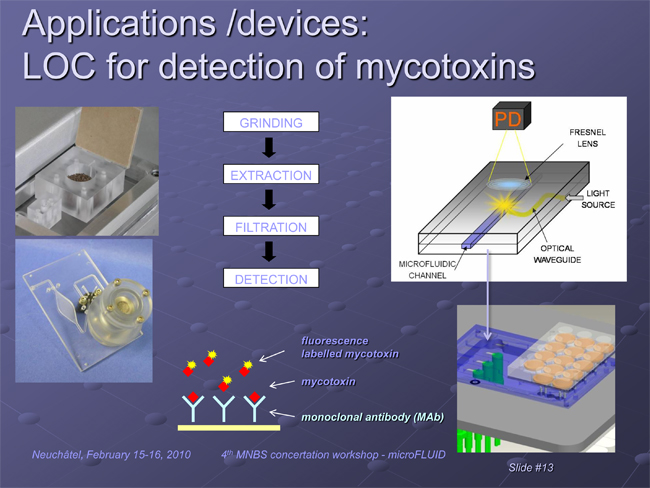

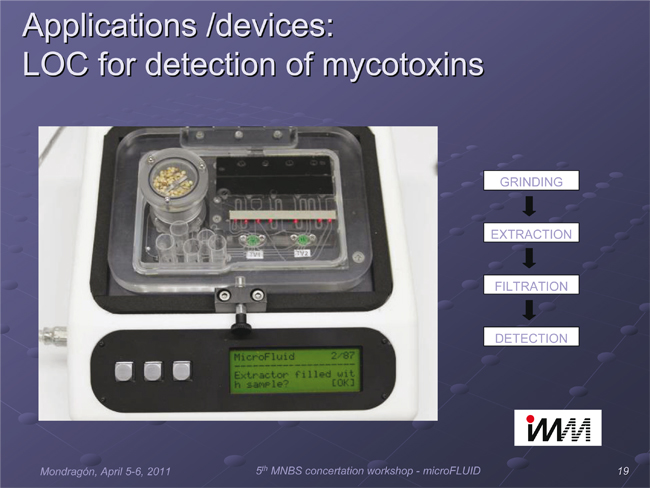

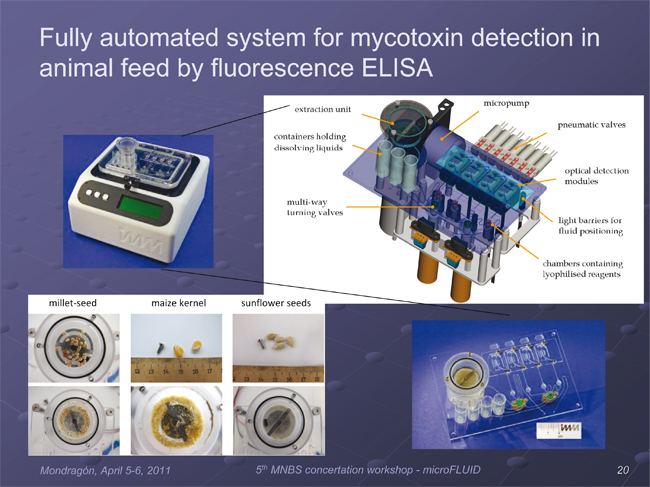

• LOC for the detection of mycotoxins in feed: mycotoxins are toxic metabolites produced by fungi that grow on food or animal feed. Mycotoxins enter the human food chain through meat or other animal products following the consumption of contaminated feed by livestock. It is now known that diseases caused by mycotoxins are responsible for serious epidemics in humans and animals. For this reason, it is of great importance to develop sensitive, accurate and cost-effective tests for the detection and quantization of mycotoxin in feed.

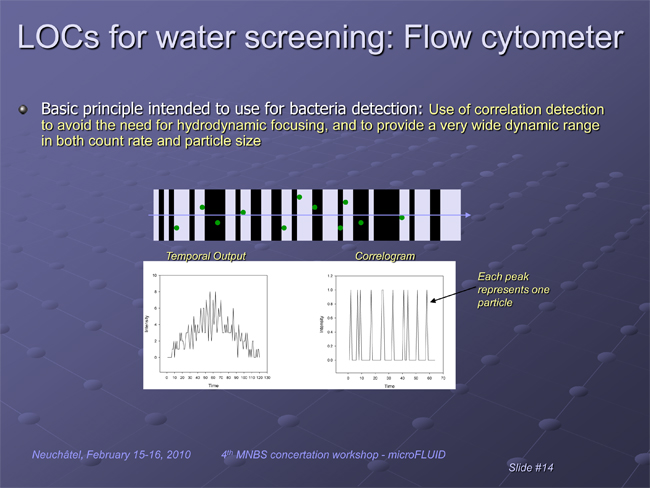

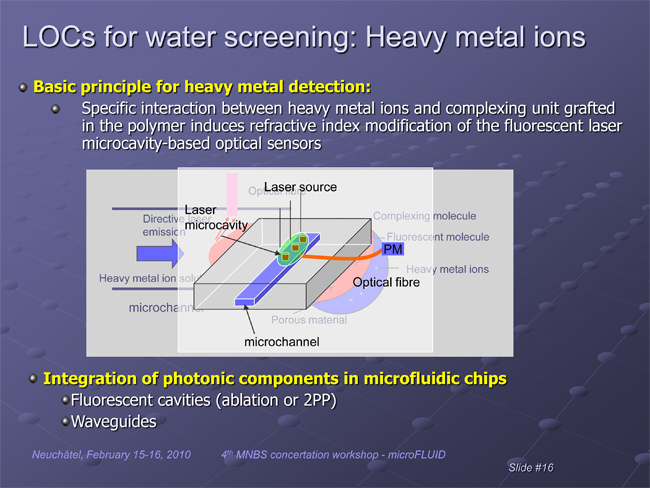

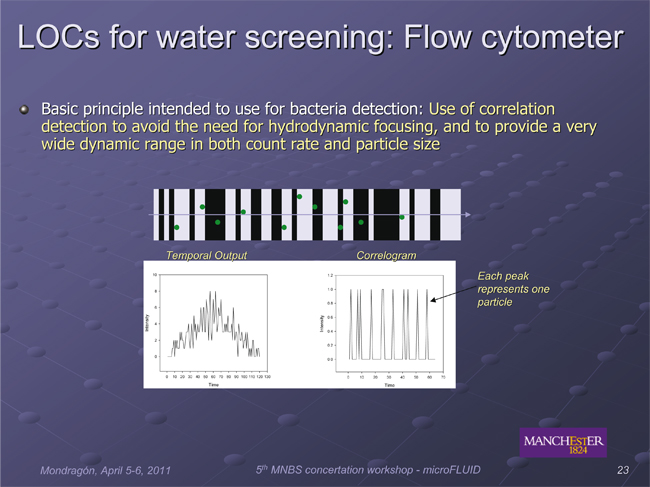

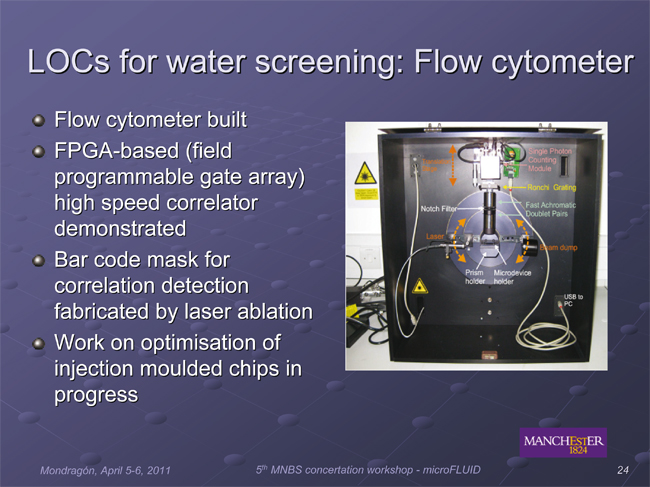

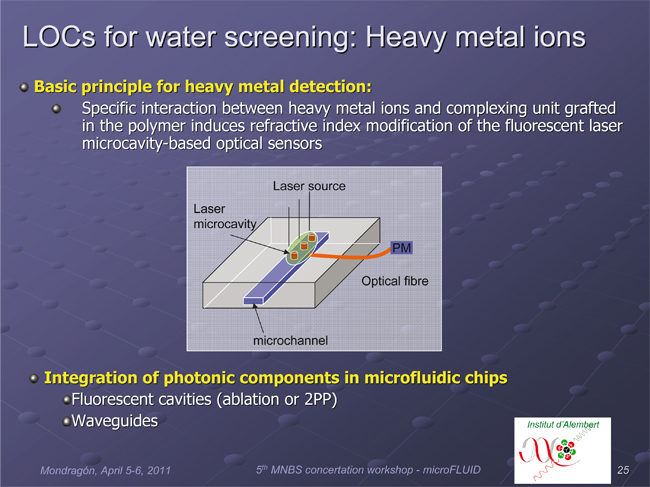

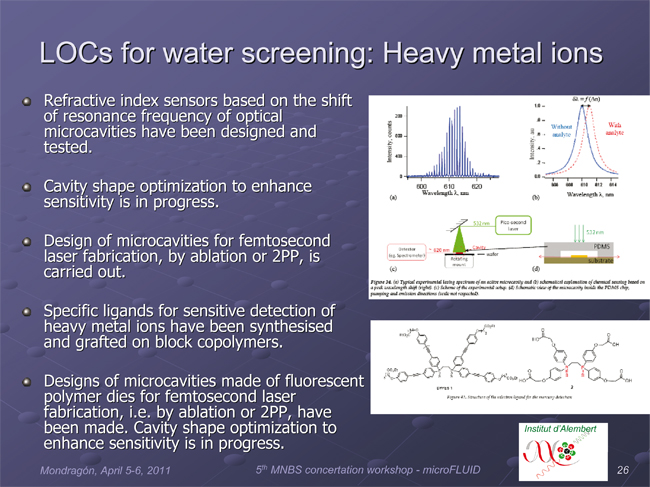

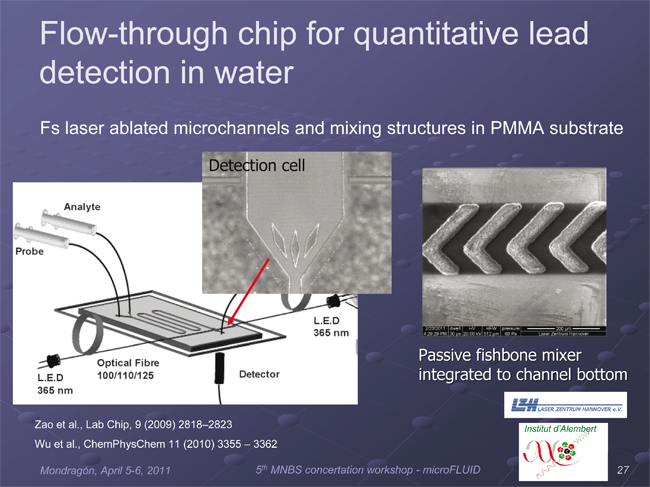

• Water screening in LOC for the detection of bacteria and heavy metal ions: water screening is very important for improving human health and preserving the environment. In the case of bacterial analyzes, quantitative bacterial culture takes a lot of time and money. Therefore, it is very important to develop a reliable screening method for differentiating liquid samples that contain significant numbers of bacteria from those that don’t. In this project, high-throughput flow cytometry will be employed as a rapid and feasible approach for detecting bacteria using size and shape sensitive light scattering methods. Hg2 +, Cd2 + and Pb2 + are the most toxic heavy metal ions that cause environmental and health problems.

For this reason, the level of heavy metal ions in drinking water is subject to strict rules.

While sophisticated analytical techniques are currently used in applications relevant to massive environmental contamination, there is still a significant need to provide cost-effective, real-time monitoring methods for the detection of traces of mercury and lead in drinking water, in polluted areas and in industrial waste streams.

- Morphological and chemical-physical characterization of the surfaces prepared with the laser to explain the observed permanent improvement of hydrophobicity.

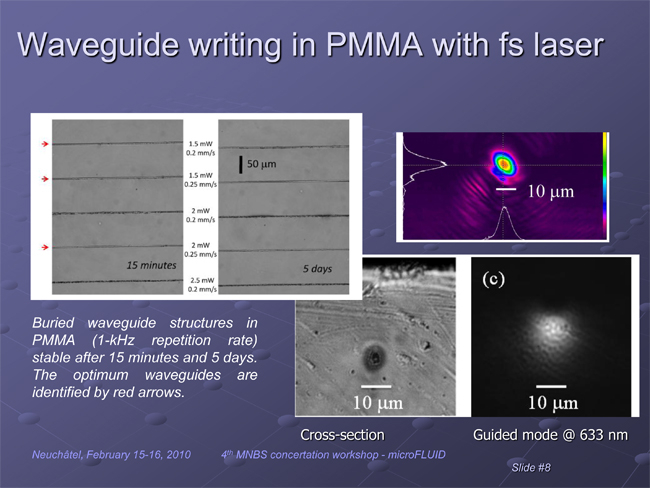

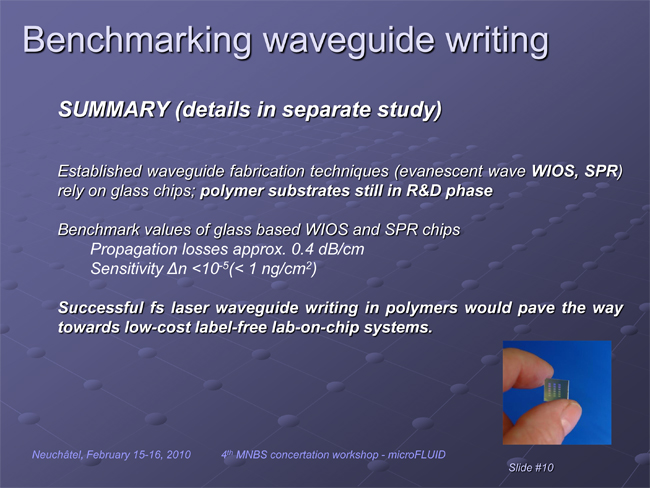

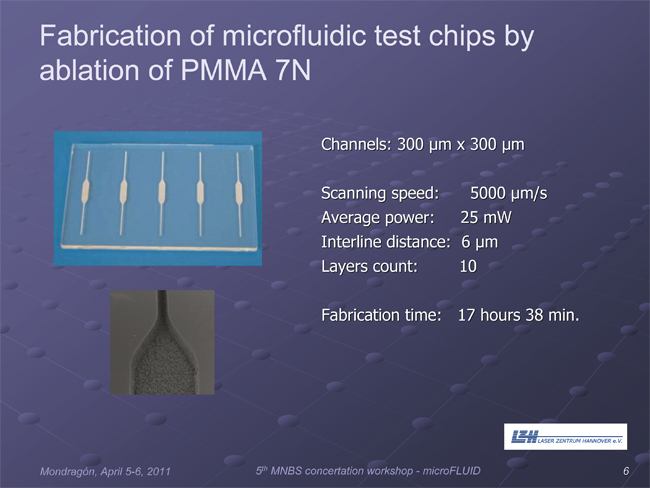

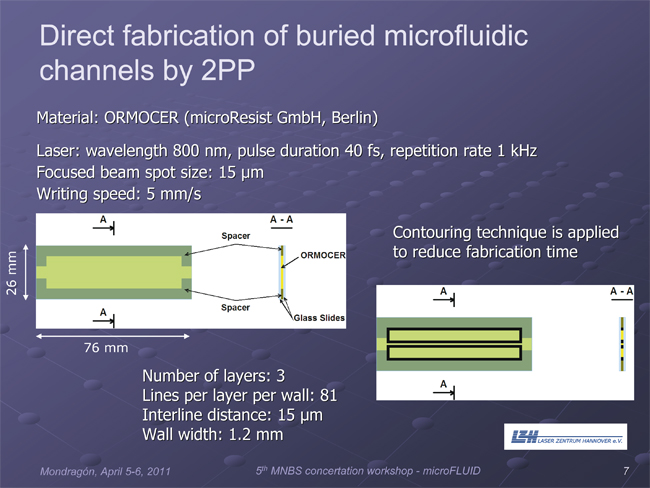

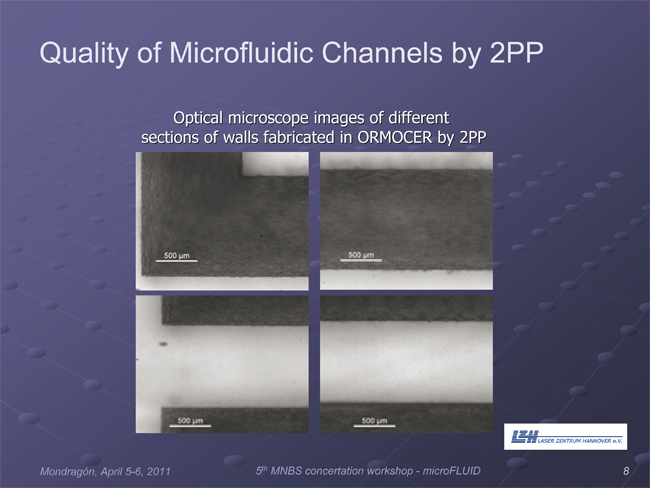

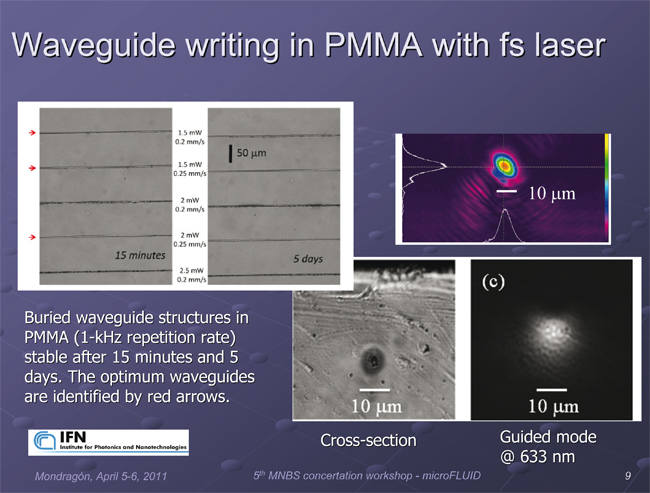

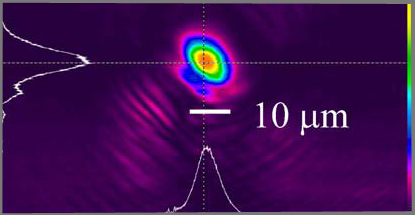

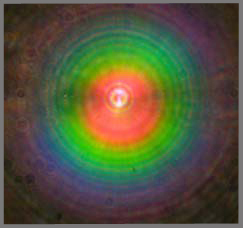

- Writing of the optical waveguide with the femtosecond laser in various polymer substrates, including PMMA and COP. The parameters for the manufacture of the guide wave have been identified. The guide is visible in the entire visible range.

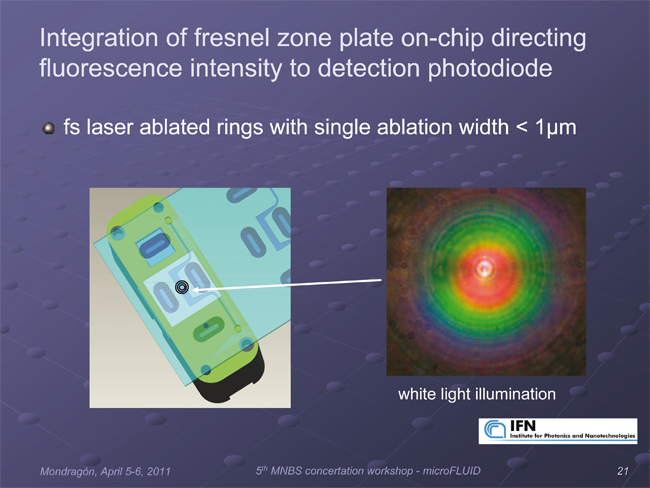

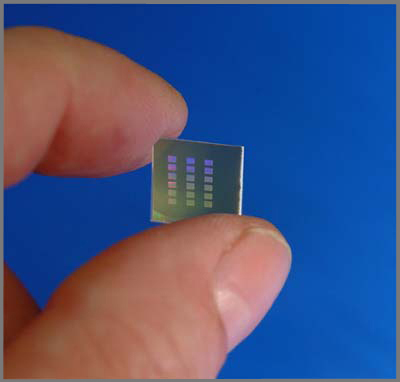

- Fresnel lenses were manufactured in polymeric LOCs to implement optical detection on the chips: extremely precise surface laser ablation was used to integrate Fresnel lenses, with very short focal length, into microfluidic chips.

- Design of LOC devices for the two applications of the project: mycotoxin detection and water screening. The devices are designed from the point of view of the system, including fluidic and optical functionality.

- Creation of a module for the extraction of mycotoxins from solid foods: an external module that can be directly interfaced with the LOC, capable of grinding the solids and extracting their mycotoxin content Identification of immunological protocols for the detection of mycotoxins by absorption or fluorescence measurements: specific antibodies for aflatoxins B1 and M1 have been isolated, purified and cloned. The antibody labeling with suitable molecules provides the optical signal for mycotoxin detection in competitive immunoassays within LOC.

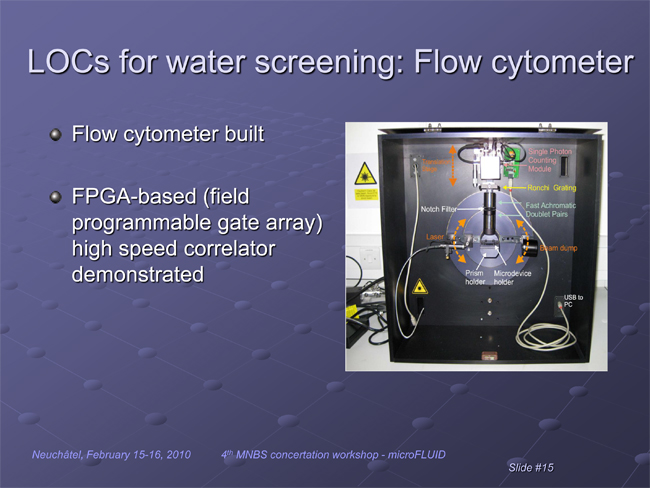

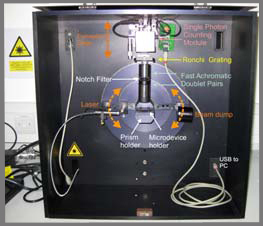

- Development of a prototype flow cytometer for bacterial detection: a flow cytometer was built for particle detection by multichannel correlation; an FPGA-based high-speed correlator was demonstrated.

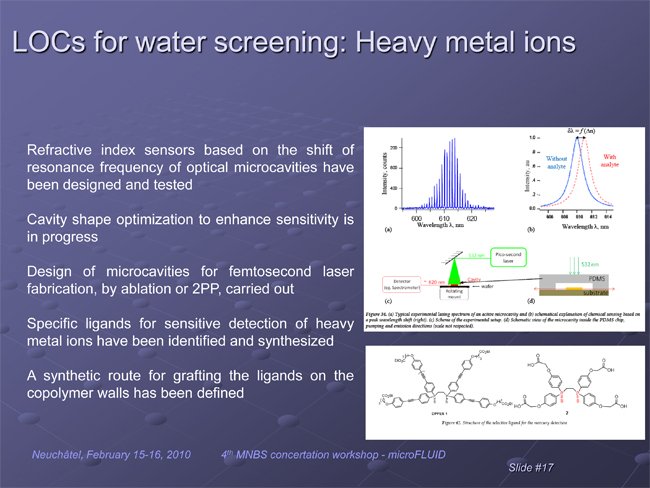

- Synthesis of ligands specific for heavy metal ions and grafting on a polymer matrix: the ligand molecules specific for Pb, Cd and Hg were synthesized and grafted on block copolymers. Laser microcavities fabricated from these materials and immersed in a flowing water sample will provide highly sensitive metal ion detection.

- An alternative approach for the detection of heavy metal ions based on fluorescence detection was developed: A Y channel with micromixing elements was used to perform a complexation reaction between the fluorescent probe and the possible heavy metal ion. This causes a change in the fluorescence signal which is detected with the devices integrated at the end of the channel.

In summary, the project generated a large amount of basic multidisciplinary knowledge, which was disseminated by the partners through publications and conference presentations. An example is the deeper understanding of the interaction between ultrashort light pulses and polymeric surfaces. On the other hand, considerable work is being carried out towards real-world applications with the development of several prototypes for mycotoxin detection and water screening.